"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Imagine a manufacturing world where machines, systems, and people are seamlessly connected—sharing real-time data to optimize processes, predict issues before they occur, and meet customer demands with speed and precision. This vision is becoming a reality thanks to cloud computing in manufacturing. As the backbone of Industry 4.0, cloud computing is revolutionizing the way manufacturers operate, innovate, and compete in a rapidly evolving market. But what exactly is cloud computing, and why is it so transformative for the manufacturing sector? Let’s dive in.

Cloud computing in manufacturing refers to the delivery of computing resources—such as servers, storage, databases, and software—over the internet (the cloud) instead of relying on local servers or personal devices. In manufacturing, it means digitizing operations, processes, and workflows to improve efficiency and innovation.

For example, rather than maintaining expensive on-premise custom software application, Cloud computing in manufacturing can access cloud-based tools to monitor production lines, manage supply chains, or analyze performance data from anywhere in the world. This shift is breaking down silos and enabling smarter, faster, and more collaborative operations.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

Enhanced Collaboration and Connectivity

Imagine a scenario where a product is designed in California, manufactured in Texas, and shipped globally—all while every stakeholder can access the same data in real-time. With cloud computing, this level of collaboration becomes effortless. Teams can share designs, monitor production progress, and address issues instantly, breaking barriers between departments, suppliers, and customers.

Real-Time Data Insights for Smarter Decision-Making

In the fast-paced manufacturing environment, decisions need to be made quickly and accurately. Cloud platforms provide real-time analytics, allowing manufacturers to track key performance metrics, identify bottlenecks, and adjust operations instantly. For instance, if a machine in the production line starts underperforming, cloud-based dashboards can alert managers and recommend solutions before delays occur.

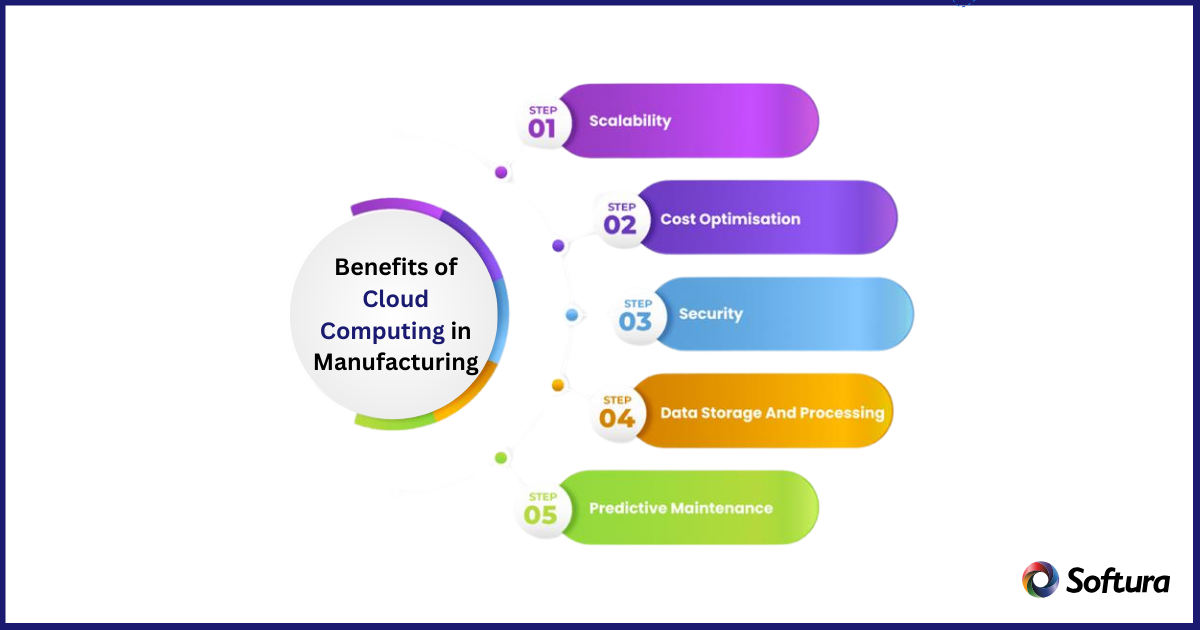

Scalability and Flexibility for Growing Businesses

One of the greatest advantages of cloud computing in manufacturing is its scalability. Whether you’re a small manufacturer or a global enterprise, you can scale up or down your cloud resources based on demand. Launching a new product? Expanding into new markets? Cloud platforms provide the flexibility to adapt quickly without incurring high infrastructure costs.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

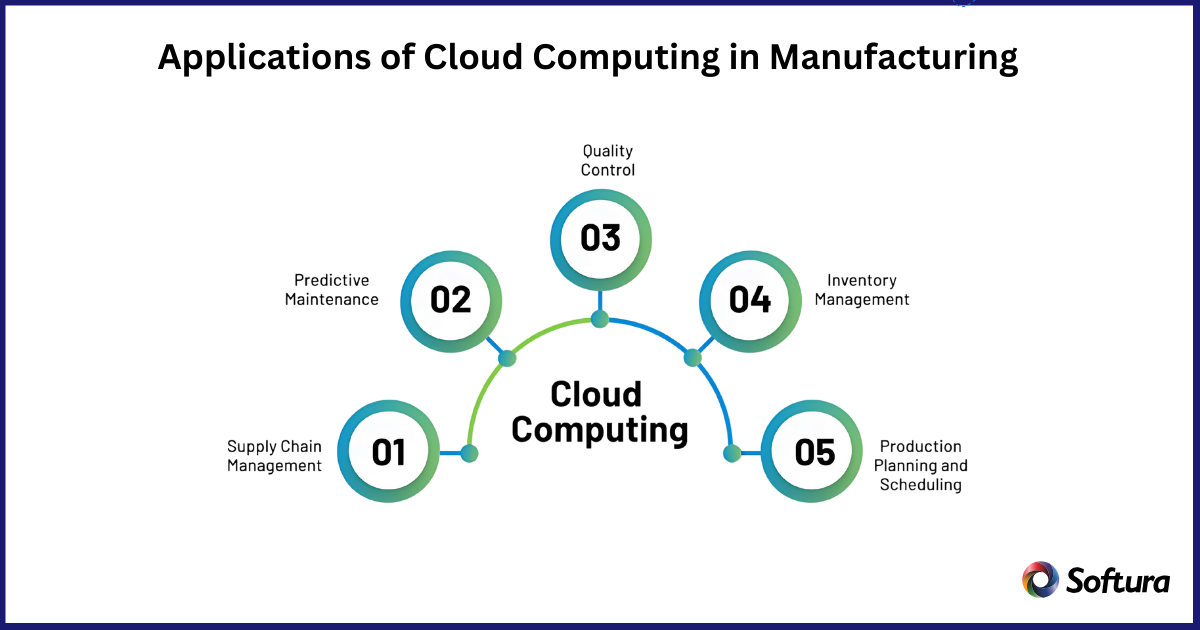

Supply Chain Management and Optimization

How do cloud computing in manufacturing keep their supply chains running smoothly amid global disruptions? The answer lies in cloud computing. By integrating supply chain data into a centralized cloud platform, manufacturers can track shipments, monitor inventory levels, and forecast demand with greater accuracy.

Smart Factory Integration and IoT Connectivity

Smart factories rely on the Internet of Things (IoT) to connect devices and machines, enabling real-time communication. Cloud computing acts as the central hub for this connectivity, allowing manufacturers to analyze IoT data, automate workflows, and ensure smooth factory operations. Imagine a factory where machines order their own replacement parts before they break down!

Quality Control and Predictive Analytics

Cloud computing in manufacturing to analyze quality control data and predict defects before they occur. For instance, an AI-driven cloud system can detect minute anomalies in production patterns, ensuring consistent product quality and reducing waste.

Maintenance Management and Downtime Reduction

Downtime is a manufacturer’s worst enemy. Cloud-based predictive maintenance tools use machine data to forecast maintenance needs, reducing unplanned downtime by up to 50%. Instead of reacting to breakdowns, manufacturers can proactively schedule repairs, saving time and money.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Industry 4.0, the fourth industrial revolution, is characterized by automation, data exchange, and smart manufacturing systems. Cloud computing serves as the foundation for this transformation by enabling:

Without cloud computing, the vision of fully autonomous and connected factories would remain out of reach.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Despite its benefits, adopting cloud computing in manufacturing isn’t without challenges. Some of the common obstacles include:

How can manufacturers overcome these challenges and fully embrace the cloud computing in manufacturing? The next section offers insights.

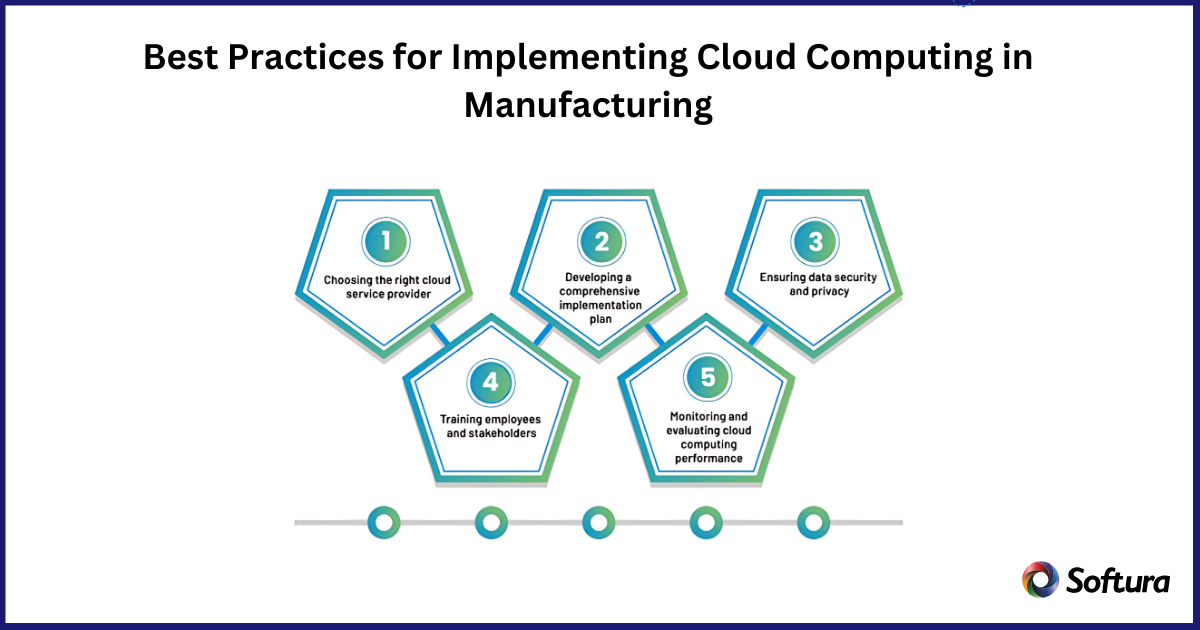

Start Small, Scale Gradually: Test cloud solutions in a specific area, such as inventory management, before rolling them out across the organization.

Choose the Right Provider: Partner with a cloud provider experienced in manufacturing to ensure they understand your unique needs.

Focus on Security: Implement strong access controls and encryption to protect your data.

Train Your Workforce: Equip employees with the skills needed to leverage cloud technologies effectively.

Continuously Monitor Performance: Regularly evaluate your cloud systems to identify areas for improvement.

SharePoint Online Migration & Enterprise Portal Development

A leading supplier in the U.S. automotive industry faced challenges with their intranet portals, which were hosted on-premises in North America and on AWS Cloud in Europe. These disparate systems led to difficulties in navigation, personalized content delivery, and user adoption. To address these issues, the company migrated to SharePoint consulting services, creating a unified enterprise portal with a modern user interface. This cloud-based solution featured a custom-built mega menu for improved navigation, personalized announcements, and enhanced search capabilities. The migration resulted in significant cost savings, streamlined information access, and increased user engagement.

Global Automobile Manufacturer's Digital Transformation

A prominent global automotive manufacturer sought to modernize its operations by integrating cloud computing into its processes. By adopting cloud-based solutions, the company enhanced its enterprise content management system, enabling seamless collaboration across departments and regions. This transformation facilitated real-time data access, improved decision-making, and supported the development of innovative automotive technologies.

Web & Mobile App Development for Automotive Parts Manufacturer

An automotive parts manufacturer aimed to improve its customer engagement and operational efficiency. By developing cloud-based web and mobile applications, the company provided real-time access to product information, streamlined order processing, and facilitated better communication with clients. The cloud infrastructure ensured scalability and flexibility, allowing the manufacturer to adapt to market demands swiftly.

Ink Manufacturer's Machine Monitoring via IoT and Cloud Integration

An ink manufacturing company sought to enhance its production efficiency by implementing an Industrial Internet of Things (IIoT) solution integrated with cloud computing. This setup enabled real-time monitoring of machinery, predictive maintenance, and data-driven decision-making. The cloud-based system provided scalability and remote accessibility, leading to reduced downtime, optimized production processes, and significant cost savings.

Looking for Offshore Dedicated Developers?

Our skilled experts are ready to help. Let's discuss your automation needs.

What’s next for cloud computing in manufacturing? Expect to see:

The future of cloud computing in manufacturing is undoubtedly in the cloud, with endless possibilities for innovation.

Cloud computing is not just a technology; it’s a game-changer for the manufacturing industry. From smarter supply chains to predictive analytics, its applications are vast and transformative. As manufacturers navigate the complexities of Industry 4.0, cloud computing will remain a cornerstone of innovation and growth. The time to embrace this technology is now—because the future of cloud computing in manufacturing.

Are you ready for your next project?

Unlock your company's full potential with our comprehensive Offshore development services. Contact our experts today to discuss how we can drive your success together.