"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

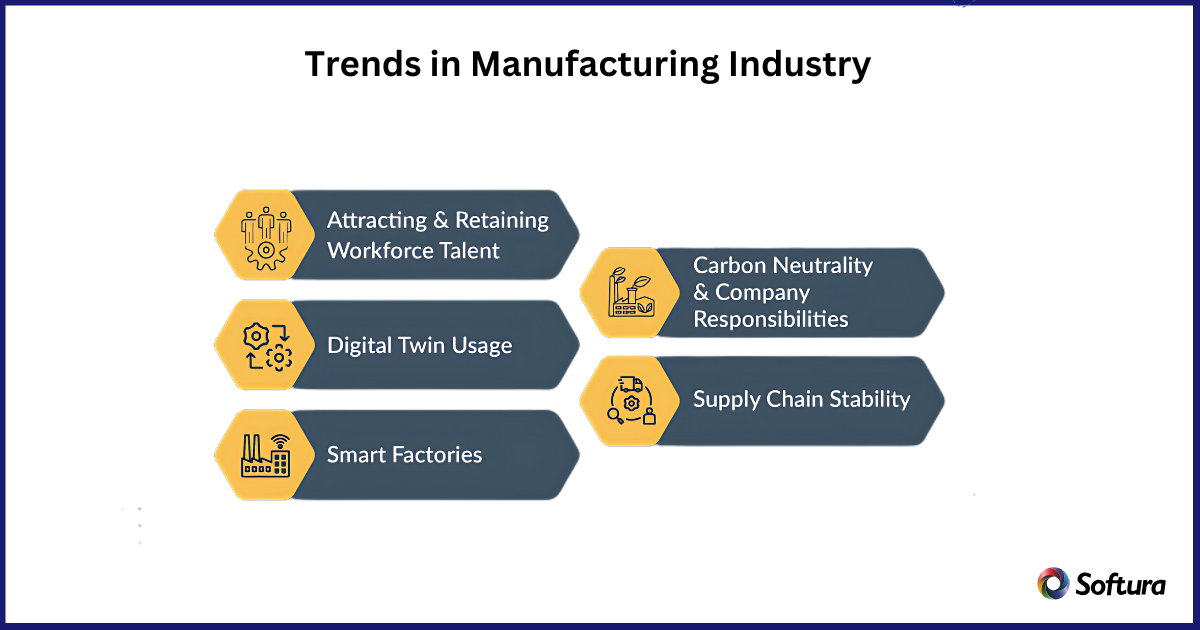

The manufacturing industry is on the brink of a significant transformation as we approach 2025. With rapid advancements in artificial intelligence development (AI), robotics, and smart technologies, manufacturers are embracing innovation to stay competitive. These trends are reshaping production processes, supply chain management, energy consumption, and more, helping companies enhance efficiency, reduce costs, and promote sustainability. In this blog, we’ll explore the top trends expected to define the manufacturing industry in 2025.

By 2025, an estimated 63% of manufacturing companies will adopt AI-driven smart factory systems. These systems leverage AI to enhance efficiency, optimize processes in real-time, and enable predictive maintenance. Smart factories are not only streamlining production but also creating a more agile manufacturing industry environment capable of adapting to market demands. With AI at the core, manufacturers can reduce downtime, improve precision, and maximize resource utilization, setting new benchmarks in operational excellence.

"Our integration with the Google Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry."

- Antonio Mediato, founder and CEO of Airzone.

The market for AI-driven predictive maintenance is expected to grow at a compound annual growth rate (CAGR) of 39% by 2025. This surge is fueled by the integration of AI and cloud computing, which empowers manufacturers to predict equipment failures and schedule maintenance proactively. The result? Reduced downtime, optimized maintenance schedules, and lower operational costs. Predictive maintenance ensures that machinery runs smoothly, ultimately improving productivity and minimizing unexpected disruptions.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Energy management systems powered by AI are revolutionizing how manufacturing Industry consume and conserve energy. By 2025, these systems are projected to reduce energy costs by up to 20% in buildings and 15% in transportation systems. Smart grids utilizing AI can lower electricity usage by 10% and reduce carbon emissions by 15%. This trend not only supports sustainability goals but also helps manufacturers comply with stricter environmental regulations while achieving significant cost savings.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

AI-based robotics are poised to revolutionize manufacturing by 2025, increasing production efficiency by up to 30%. These robots excel at performing complex tasks with high precision, adapting to new challenges, and operating continuously without fatigue. By integrating these technologies, manufacturers can achieve faster production cycles, reduce errors, and handle large-scale operations more effectively. The era of smart robotics is redefining manufacturing, making it smarter, faster, and more flexible.

"By analyzing the data from our connected lights, devices and systems, our goal is to create additional value for our customers through data-enabled services that unlock new capabilities and experiences."

- Harsh Chitale, leader of Philips Lighting’s Professional Business.

Supply chains are becoming more intelligent, thanks to AI-driven predictive tools. By 2025, businesses can expect a 30% to 50% improvement in demand forecasting accuracy through AI systems. This precision enables manufacturers to better anticipate market demand, reduce forecasting errors, and optimize inventory management. The result is a more streamlined supply chain, lower costs, and improved customer satisfaction—key factors for success in a highly competitive market.

AI’s ability to analyze vast amounts of data, including visual inputs, is transforming quality control in manufacturing industry. By 2025, AI systems will increase defect detection rates by up to 90%, significantly improving product quality and reducing waste. Advanced AI algorithms can identify even microscopic imperfections and irregularities, ensuring that only the highest-quality products reach the market. This trend is setting new standards for precision and reliability in the manufacturing industry.

Collaborative robots, or cobots, are changing the way humans and machines work together. By 2025, cobots will augment 60% to 70% of manufacturing insdustry tasks. These robots are designed to assist human workers by taking over repetitive, dangerous, or precision-demanding jobs, boosting productivity and safety. Cobots are easy to integrate into existing workflows, making them a cost-effective solution for manufacturers aiming to enhance efficiency without replacing their workforce.

Looking for Offshore Dedicated Developers?

Our skilled experts are ready to help. Let's discuss your automation needs.

AI is playing a critical role in minimizing waste in manufacturing Industry. By 2025, AI-driven systems are projected to reduce waste production by 20% to 25%. Through intelligent process optimization and real-time monitoring, manufacturers can identify inefficiencies and implement measures to eliminate them. This not only improves resource utilization but also supports sustainability efforts, making manufacturing operations more environmentally friendly and cost-effective.

With the increasing reliance on digital technologies, cybersecurity has become a top priority for manufacturers. AI-powered cybersecurity tools can analyze threats in real-time, detect vulnerabilities, and prevent cyberattacks. By 2025, these systems are expected to reduce costs associated with data breaches and cyberattacks by up to 30%. Protecting intellectual property and ensuring uninterrupted operations are critical for maintaining trust and efficiency in the manufacturing sector.

Approximately 74% of warehouses are expected to adopt AI by 2025 to improve inventory handling, picking, and packing processes. AI-powered custom software development systems bring unprecedented efficiency and accuracy to warehousing operations, enabling faster order fulfillment and reducing errors. With automation at the forefront, manufacturers can streamline logistics, meet customer demands more effectively, and stay ahead in a competitive market.

The trends shaping the manufacturing industry in 2025 underscore the growing importance of AI and smart technologies. From predictive maintenance and energy management to robots and defect detection, these innovations are setting the stage for a smarter, more efficient, and sustainable manufacturing sector. By embracing these advancements, companies can gain a competitive edge, enhance productivity, and drive growth in a rapidly evolving landscape

Are you ready for your next project?

Unlock your company's full potential with our comprehensive Offshore development services. Contact our experts today to discuss how we can drive your success together.